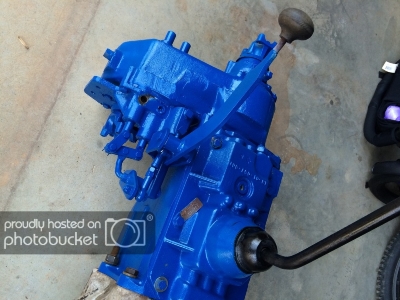

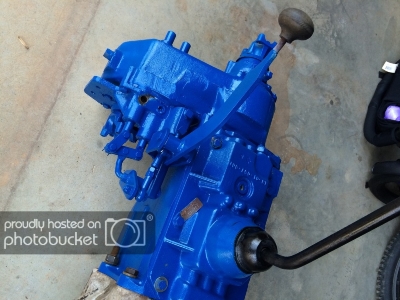

I got it today but struggling to find the gear ratio. 76 was a split year some got the narrow ratio and some got the wide. This is a t-18 1b. 77-79 were all wide ratio. He said he took it out because first was useless so I took his word. Spinning the front out put and counting the rotations of the front while watching the rear keeps coming up with 13-1. I'd just really like to verify it before getting all excited.