The black sheep 89 Bronco II

- Thread starter TCBronco

- Start date

No, I didn't get a chance yet. I plan to drive it around and let it idle for a few hours this weekend to see what its got. I also changed the flow of the fuel a little where before the low pressure pump supplied fuel to the filter under the hood and any extra returned to the tank from the filter, now all the fuel from the low pressure pump goes through the filter and to the high pressure pump. I think that should make a big difference because before the high pressure pump had to suck the fuel from the filter and now it should be pressurized fuel going to it.

its not running like a fox body mustang where you have a feed line with a regulator at the motor and then a return line to the tank?

It's been awhile since I updated this. I've been making some changes so I'll bring it up to speed. Last year I was having problems with fuel delivery, since then I put a stock tank back in and that's fixed all those problems so far. I also added a set of trail-gear sliders, the 58" kit fit perfectly. They're welded to the frame and I ended up adding some polyurethane bushings to tie them into the body mounts as well.

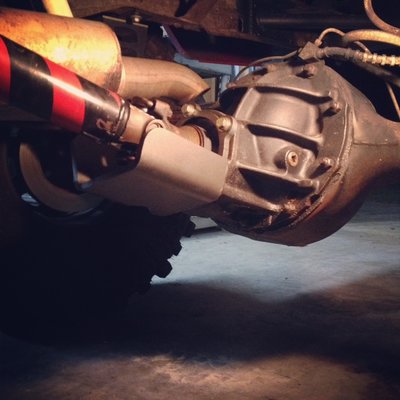

Last weekend I started redoing the exhaust, the headers hung below the frame and the muffler hung below the frame so I've been looking for a reason to redo that anyway. Anytime I've ever taken something to an exhaust shop I've never been happy with the results so this time I decided to do it myself. I got a flowmaster hushpower muffler, hedman shorty headers and some mandrel bends and y-pipe from summit and fit it all together. I still have to put it back on after welding and hang the muffler.

While I was doing the exhaust I figured I might as well raise the transfercase up above the frame rails so I can put a flat skid plate on it like all the cool kids. I made an adjustable transmission mount from some 2x2 square tubing. This raised my front driveshaft up quite a bit though so I'm hoping it doesn't come apart when the driver side droops down. I'm still working on the skidplate but it will be 3/16" steel plate I had.

I also got a march performance serpentine belt bracket kit for christmas as my belt would eventually start squealing due to the pulley's not being exactly lined up.

Next up I have some curry johnny joints ready to go in for the bottom links, I'm going to be raising the mounting on the frame and axle as much as I can, eventually.

Last weekend I started redoing the exhaust, the headers hung below the frame and the muffler hung below the frame so I've been looking for a reason to redo that anyway. Anytime I've ever taken something to an exhaust shop I've never been happy with the results so this time I decided to do it myself. I got a flowmaster hushpower muffler, hedman shorty headers and some mandrel bends and y-pipe from summit and fit it all together. I still have to put it back on after welding and hang the muffler.

While I was doing the exhaust I figured I might as well raise the transfercase up above the frame rails so I can put a flat skid plate on it like all the cool kids. I made an adjustable transmission mount from some 2x2 square tubing. This raised my front driveshaft up quite a bit though so I'm hoping it doesn't come apart when the driver side droops down. I'm still working on the skidplate but it will be 3/16" steel plate I had.

I also got a march performance serpentine belt bracket kit for christmas as my belt would eventually start squealing due to the pulley's not being exactly lined up.

Next up I have some curry johnny joints ready to go in for the bottom links, I'm going to be raising the mounting on the frame and axle as much as I can, eventually.

Very nice. Have you considered getting those lowers up more? Like a lot smaller tab higher up on the frame. And move the axle side around to the back of the tube. Just looks like they are waiting to get you hung up.

Yeah definitely, that's the plan. I'm gonna chop off as much of the frame side lower link mount as I can and move the bolt hole higher up and redo the brackets on the axle. I haven't yet because the old transmission mount wrapped around the bottom of the frame on the passenger side. Now that's gone so changing the lower links is next

Looks good..you going to extend the skid plate to cover oil pan?