Bringing this back from the dead, I haven't updated this in a while but I've been getting some stuff done on it. A while back I ordered a new tailgate for it. It's made from original ford tooling so its pretty quality.

View attachment 7752

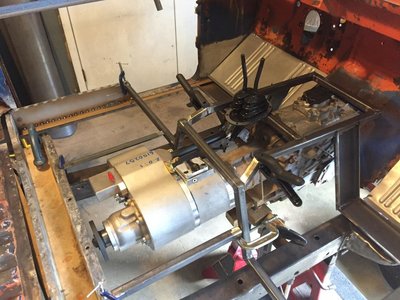

For a while I've been trying to get rid of all the rust, this is some of the worst of it.

View attachment 7753

View attachment 7754

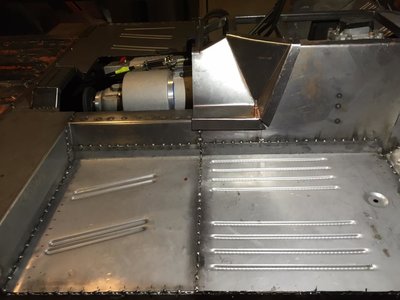

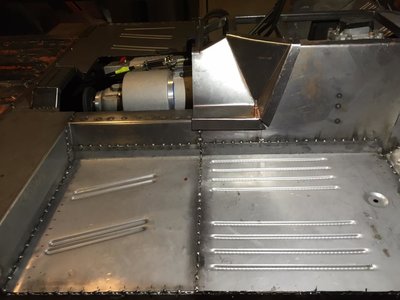

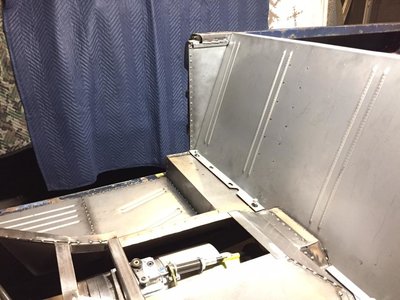

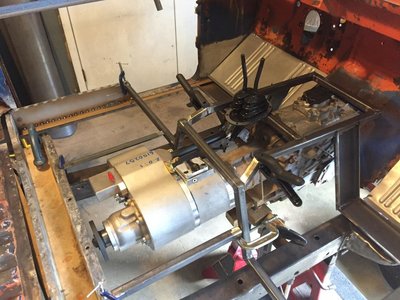

I've made pretty good progress getting the floor pans replaced. I started by setting the transfercase slightly above the bottom of the frame rail and built the floor around it. I hope I'll be able to have a smooth belly pan.

I cut out the bottom of the driver side door post and cowl and sprayed the inside with rust converter.

I ended up cutting out all of the floor supports and replacing them with 1" square tubing and some 4" square tubing that I chopped up to make the body mounting crossmember.

I cut the top of the cowl out and found even more rust underneath. I cut it out and put a patch piece in, coated everything with rust converter and some zinc paint and welded in the new cowl piece.

Since the transmission tunnel is alot bigger than the original one, I made some cardboard templates before I cut everything out of 18 ga.

Right before this point I noticed there wasn't much room for the passenger seat. I was planning to use some f-150 seats I had but when I was test fitting them, they didn't fit very well so I decided to get some new seats. I ordered the prp daily drivers and waited for them forever. They turned out nice though. The f-150 seats were about 55lbs a piece so it also saved some weight.

I had to create the big notch in the transmission tunnel to have enough room for the passenger seat. The drivetrain in early broncos is pushed off to the right side so the driver side has alot more room than the passenger.